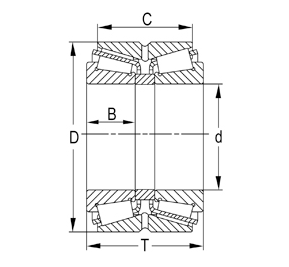

| Расследование | Bearing No. | Boundary dimensions(mm) | Базовая нагрузка (кН) | Limiting speed(rpm ) | Mass | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| д | Д | T | C | Б | Dynamic(Cr) | Static(Cor) | Смазка | Масло | (Кг) | |||

| 10979/710 | 710 | 950 | 240 | 175 | 106 | 4300 | 13200 | 250 | 320 | 445 | ||

| 3519/750X2/HC | 750 | 1000 | 255 | 190 | 112 | 4900 | 15100 | 230 | 310 | 535 | ||

| 3519/750 | 750 | 1000 | 264 | 194 | 112 | 4850 | 15600 | 230 | 310 | 546 | ||

| 3519/80 | 800 | 1060 | 270 | 204 | 115 | 6250 | 15200 | 220 | 300 | 606 | ||

| 3519/850 | 850 | 1120 | 268 | 188 | 118 | 6230 | 18700 | 210 | 270 | 645 | ||

| 3519/900 | 900 | 1180 | 275 | 205 | 122 | 6950 | 21300 | 200 | 260 | 763 | ||

| 10979/1120 | 1120 | 1460 | 335 | 250 | 158 | 9000 | 29500 | 160 | 210 | 1350 | ||

Tapered roller bearings offer several advantages due to their unique design. They excel in handling both radial and axial loads by distributing these forces evenly across the bearing surfaces. This capability makes them suitable for applications where heavy combined loads and high axial rigidity are required, such as in automotive transmissions and wheel hubs. Tapered roller bearings also provide excellent durability and reliability in harsh operating conditions due to their ability to accommodate misalignment and shaft deflection. Their design minimizes frictional losses, enhancing energy efficiency, while their separable components facilitate easy assembly, disassembly, and maintenance. Overall, tapered roller bearings are valued for their robustness, versatility, and efficiency in demanding industrial and automotive applications.