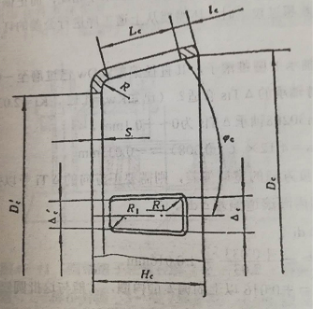

Single-row tapered roller bearings consist of an inner ring with a tapered roller track, an outer ring, tapered rollers and a basket-shaped cage. They mainly bear radial and axial combined loads, mainly radial loads. Almost all tapered rollers use a basket-shaped cage stamped from low-carbon steel plates. Its structural shape is shown in the figure below. This cage has a simple structure, good strength and easy processing, and is currently a structure commonly used by bearing companies at home and abroad.

Tapered roller bearings using a basket-shaped cage are designed with a small non-working rib on the inner ring.

Its function is to make the inner ring, roller and cage an inseparable assembly, so as to facilitate the assembly and installation of the bearing. However, due to the presence of a small rib on the inner ring, the basket-shaped cage manufactured according to the product drawing size cannot directly carry out the assembly process of the inner ring and roller of the bearing. For this reason, the basket-shaped cage must be expanded again after stamping and before the bearing is assembled, that is, the small end of the cage must be expanded so that after the roller is installed in the cage pocket, the inner ring with a small rib can be smoothly installed. Then, the small end of the cage is compressed to a size close to the finished product specified in the product drawing using a special assembly die. When assembling the bearing, the roller should be installed in the cage pocket first, and then the inner ring should be placed. The method of installing tapered rollers in the cage pocket is mostly done manually in medium and small batch production, and can be done by roller loading machinery or automated devices in large batch production. After the expanded cage is loaded with rollers and inner rings, it is compressed to a size close to the finished product specified in the product drawing using a special assembly die. Generally, the expansion process of the cage is carried out in the cage manufacturing workshop, while the compression process of the cage is carried out in the bearing assembly workshop after the rollers and inner rings are installed. Therefore, using the assembly die to compress the cage is the main task of the assembly workshop. The main function of the tapered roller bearing assembly mold is to compress the expanded basket-shaped cage and restore it to the size and geometry specified in the product drawing to ensure the normal operation of the bearing and the requirements for rotational flexibility and noise. The expansion or contraction of the cage is completed by the press and the mold. Correct adjustment of the press and the optimized design of the mold can ensure that the inner ring, roller and cage of the tapered roller bearing are tightly combined. After the contraction of the basket-shaped cage is completed, the main assembly process of the tapered roller bearing is completed. Subsequently, demagnetization, cleaning, and inspection of the nominal width deviation, rotational flexibility, noise and various runout of the internal components are carried out, and qualified finished tapered roller bearings can be installed on various equipment for normal use.

RHF Tapered Roller Bearing:

http://www.rhfbearing.com/products//155.html